3D Printing Technology in Dental Prosthetics in Alanya: Next-Generation Designs

3D printing technology, rapidly spreading in dental clinics in Alanya, provides great ease in designing and producing personalized dental prosthetics. This article discusses the advantages, processes, and reasons to choose 3D printed dental prosthetics. Prosthetics produced with 3D printing technology in Alanya’s dental clinics offer patients a new experience in both comfort and aesthetics. These prosthetics, made with an innovative approach and advanced technology, enhance dental treatments…

3D Printing Technology in Dental Prostheses in Alanya: Next Generation Designs

Alanya, the pearl of the Mediterranean, attracts attention not only with its historical beauties and beaches but also with its innovations in health tourism. The technological revolution in 3D printed dental prostheses in Alanya particularly draws the interest of both local and foreign patients. 3D printing technology, which has replaced traditional dental prosthesis manufacturing methods, offers unique advantages in terms of precision, speed, and personalization. This article will examine in detail how dental clinics in Alanya use 3D printing technology and the benefits this technology offers to patients.

The Place of 3D Printing Technology in Dentistry

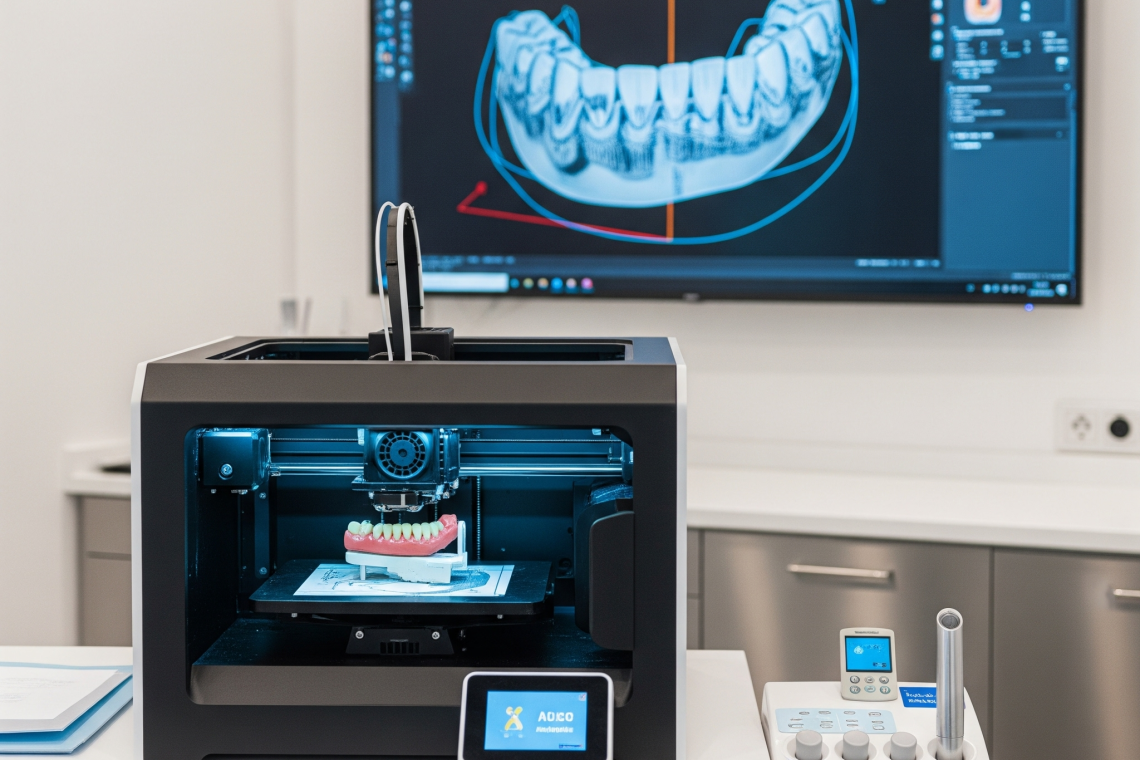

Three-dimensional printing technology refers to the process of producing physical objects from digital files. In the field of dentistry, this technology has created revolutionary changes in the production of prostheses, crowns, bridges, and implants. This technology used in the production of 3D printed dental prostheses in Alanya works on the principle of layer-by-layer material accumulation and enables extremely precise results.

Traditional methods involved long processes such as taking plaster impressions from patients, preparing molds in the laboratory, and manual prosthesis production. However, thanks to 3D printing technology, this process has become both faster and more precise. The patient's oral structure is transferred to the computer environment using digital scanning devices, and prosthesis design is carried out with special software.

Working Principle of the Technology

In the 3D printing process, the patient's intraoral structure is first digitally imaged using intraoral scanners. This scanning process takes only a few minutes and is quite comfortable. The obtained data is transferred to special CAD/CAM software for digital prosthesis design. After the design is completed, the prosthesis is produced in the 3D printer using appropriate materials.

The materials used in this process have biocompatible and durable properties. Particularly, materials such as dental resins, ceramic composites, and titanium alloys are preferred. These advanced materials used in the production of 3D printed dental prostheses in Alanya provide long-lasting and aesthetically satisfying results.

The Spread of 3D Printing Technology in Alanya

Alanya is one of Turkey's leading destinations in health tourism. Modern dental clinics in the city adopt the latest technologies and continuously follow innovations to provide quality service to their patients. The use of 3D printing technology in dental prosthesis production is among these innovations.

Dental centers in Alanya are determined to provide services according to international standards. Accordingly, investments in the field of 3D printed dental prostheses in Alanya are quite comprehensive. Modern equipment, experienced technicians, and expert dentists come together to achieve perfect results.

Health Tourism and Technological Infrastructure

The main reasons for preferring Alanya in terms of health tourism include competitive prices, high quality standards, and technological infrastructure. Patients coming from European countries, in particular, prefer Alanya both for vacation and dental treatments.

With the spread of 3D printing technology, patients can get their prostheses in a shorter time and with fewer sessions. This situation provides a great advantage especially for patients coming from abroad for short stays. Treatment processes have been optimized and patient satisfaction has increased thanks to 3D printed dental prostheses in Alanya.

Advantages of Prostheses Produced with 3D Printing

Compared to traditional methods, dental prostheses produced with 3D printing technology offer many important advantages. These advantages both increase patient comfort and improve treatment quality.

Precision and Fit

One of the greatest advantages of 3D printing technology is its micron-level precision. Thanks to digital scanning and design processes, prostheses provide perfect fit to the patient's oral structure. This precision minimizes discomfort that may be experienced while wearing the prosthesis and optimizes chewing function.

3D printed dental prostheses in Alanya provide 20-30% better fit compared to traditional methods. Thanks to this fit, patients can use their prostheses more comfortably in daily life and feel more confident in their social activities.

Speed and Efficiency

While traditional prosthesis production processes usually take 2-3 weeks, 3D printing technology can reduce this time to 3-5 days. This acceleration offers important advantages for both patients and doctors. While patients get their prostheses in a shorter time, doctors can serve more patients.

This speed advantage is particularly critical for patients in emergency situations or those making short visits. The efficiency in the production process of 3D printed dental prostheses in Alanya further strengthens the city's health tourism potential.

Personalization Possibilities

3D printing technology allows the production of prostheses customized according to each patient's individual needs. Tooth color, shape, size, and even the textural properties of chewing surfaces can be personalized. This approach ensures that the prosthesis provides perfect results both functionally and aesthetically.

An interactive work is carried out between the patient and the doctor during the digital design process. The prosthesis design is shaped considering the patient's expectations and aesthetic preferences. This approach significantly increases patient satisfaction.

Material Technologies Used

The materials used in 3D printing technology directly affect the quality and durability of the prosthesis. The materials used in the production of 3D printed dental prostheses in Alanya are international standard and latest technology products.

Biocompatible Resins

Dental resins are one of the most frequently used materials in 3D printing. These materials are formulated to adapt to the oral environment and pass biocompatibility tests. Modern resins show excellent performance in terms of color stability, wear resistance, and mechanical durability.

Especially flexible resins are used for soft prosthesis liners and increase patient comfort. These materials maintain their shape even during long-term use and require no maintenance.

Ceramic Composites

Ceramic composite materials are preferred for patients with high aesthetic expectations. These materials provide the closest appearance to natural tooth color and transparency. Additionally, they offer long-lasting use thanks to their high durability properties.

Ceramic composites used in the production of 3D printed dental prostheses in Alanya go through special sintering processes and reach maximum density. This process optimizes the mechanical properties of the prosthesis and minimizes the risk of fracture.

Metal Alloys

Metal alloys are used especially in partial prostheses and implant-supported prostheses. Titanium and cobalt-chromium alloys are preferred due to their high durability and biocompatibility properties. Thanks to 3D printing technology, parts with complex geometries can be produced from these metals.

In the metal printing process, powdered metal particles are melted with laser or electron beam and joined layer by layer. This process enables more homogeneous and flawless structures compared to traditional casting methods.

Treatment Process and Patient Experience

One of the greatest advantages of prosthesis production with 3D printing technology from the patient's perspective is that the treatment process is comfortable and fast. Many difficulties experienced in traditional methods have been eliminated thanks to this technology.

Initial Examination and Planning

The treatment process begins with a detailed oral examination. The patient's oral health status is evaluated and prosthesis needs are determined. At this stage, the 3D printed dental prostheses in Alanya option is introduced to the patient and its advantages are explained.

Digital treatment planning is shaped according to the patient's expectations and clinician's recommendations. During this planning process, the aesthetic and functional features of the prosthesis are simulated in advance and shown to the patient.

Digital Impression Taking

Traditional plaster impression taking method has been replaced by intraoral scanners. These devices scan the inside of the mouth in seconds and obtain high-resolution 3D images. This process is extremely comfortable for the patient and does not create a feeling of nausea.

The obtained digital data is immediately transferred to the computer environment and the design process begins. This approach prevents data loss and increases precision.

Design and Approval Process

During the digital design process, the patient takes an active role and can see the shape and color of the prosthesis. Necessary corrections can be made instantly and patient approval is obtained. This interactive approach significantly increases the rate of meeting expectations of the final product.

The software used in the design process of 3D printed dental prostheses in Alanya enables effective communication between the patient and the doctor and improves treatment quality.

Quality Control and Warranty System

In 3D printing technology, quality control is meticulously applied at every stage of the process. All stages from digital design to physical production are subject to strict quality standards.

Pre-Production Controls

Before the printing process begins, design files are checked by expert technicians. The dimensional accuracy, aesthetic compatibility, and functional features of the prosthesis are evaluated. This control process plays a critical role in preventing production errors.

Material quality is also an important part of pre-production controls. The expiration dates, storage conditions, and chemical properties of the materials to be used are meticulously examined.

Post-Production Evaluations

After the printing process is completed, prostheses go through detailed quality controls. Parameters such as dimensional accuracy, surface quality, color compatibility, and mechanical durability are measured and their compliance with standards is verified.

Quality control processes applied in the production of 3D printed dental prostheses in Alanya are carried out in accordance with international standards and prioritize patient safety.

Cost Analysis and Accessibility

With the spread of 3D printing technology, prosthesis costs have also become more reasonable. Although initial investment costs are high, final patient costs have decreased thanks to mass production possibilities and labor savings.

Comparison with Traditional Methods

Traditional prosthesis production costs consist of labor, material, and time factors. 3D printing technology significantly reduces labor and time costs. Additionally, standardization reduces error rates and minimizes remake costs.

The costs of 3D printed dental prostheses in Alanya can be half of similar services in European countries. This cost advantage is one of the main motivations for health tourism.

Long-Term Economy

The long-term economic advantages of 3D printed prostheses should also be considered. These prostheses provide cost savings in the long term as they are more durable and require less maintenance. Additionally, they can be reproduced from the same digital file when needed.

From the patient's perspective, the comfort of the prosthesis and its long-lasting use is an important investment in terms of quality of life.

Future Perspectives and Innovations

3D printing technology is a dynamic field that is constantly developing. Advances in materials science, innovations in software technologies, and increases in production speed are shaping the future of this technology.

New Material Technologies

Research and development studies focus on developing more durable, more aesthetic, and more functional materials. Nano technology applications, antibacterial materials, and self-healing composites are among the materials that may be used in the future.

These innovations are closely followed in the field of 3D printed dental prostheses in Alanya and suitable ones are implemented in clinical practice.

Artificial Intelligence Integration

Artificial intelligence algorithms have begun to be used to further optimize the prosthesis design process. These systems can analyze the patient's anatomical features to suggest the most suitable prosthesis design and support the doctor's decision-making process.

Machine learning algorithms can analyze data from past cases to predict success rates and identify risk factors in advance.

Patient Safety and Biocompatibility

Patient safety is the top priority in 3D printing technology. All materials used are selected and tested in accordance with international biocompatibility standards.

Sterilization and Hygiene

Hygiene rules are meticulously applied in the 3D printing process. Production environments are maintained at clean room standards and contamination risk is minimized. After the printing process, prostheses are subjected to appropriate sterilization methods.

All equipment used in the production of 3D printed dental prostheses in Alanya undergoes regular maintenance and calibration processes, and patient safety is continuously guaranteed.

Long-Term Follow-up

After the prosthesis is fitted, patients are called for regular check-ups and the performance of the prosthesis is evaluated. During this follow-up process, the compatibility of the prosthesis with oral tissues, wear status, and functional performance are monitored.

Digital files are archived so that prostheses with the same specifications can be produced when needed in the future. This approach provides important advantages in the patient's long-term treatment planning.

3D printed dental prostheses in Alanya technology emerges as one of the most important innovations in modern dentistry. This technology provides superiority over traditional methods in terms of precision, speed, personalization, and cost effectiveness.

Alanya's health tourism potential and technological infrastructure allow optimal use of 3D printing technology. Perfect results are achieved by bringing together experienced doctors, modern equipment, and quality materials.

It is predicted that this technology will develop further in the future and new applications will emerge. Artificial intelligence integration, new material technologies, and optimizations in production processes will further increase prosthesis quality.

From the patients' perspective, 3D printing technology offers a more comfortable, faster, and more economical treatment option. These advantages make Alanya a preferred destination in dental health.

In conclusion, 3D printed dental prostheses in Alanya technology provides a quality, reliable, and accessible service that can be benefited from by both local and international patients. The spread of this technology is creating new standards in dental health and maximizing patient satisfaction.